Rogowski coil

A Rogowski coil, named after Walter Rogowski, is an electrical device for measuring alternating current (AC) or high speed current pulses. It consists of a helical coil of wire with the lead from one end returning through the centre of the coil to the other end, so that both terminals are at the same end of the coil. The whole assembly is then wrapped around the straight conductor whose current is to be measured. Since the voltage that is induced in the coil is proportional to the rate of change (derivative) of current in the straight conductor, the output of the Rogowski coil is usually connected to an electrical (or electronic) integrator circuit in order to provide an output signal that is proportional to the current.

This type of coil has many advantages over other types of current transformers, the most notable being that it is not a closed loop, because the second terminal is passed back through the center of the toroid core (commonly a plastic or rubber tube) and connected along the first terminal. This allows the coil to be open-ended and flexible, allowing it to be wrapped around a live conductor without disturbing it.

Furthermore, since a Rogowski coil has an air core rather than an iron core, it has a low inductance and can respond to fast-changing currents. Also, because it has no iron core to saturate, it is highly linear even when subjected to large currents, such as those used in electric power transmission, welding, or pulsed power applications. A correctly formed Rogowski coil, with equally spaced windings, is largely immune to electromagnetic interference.

A good set of traditional and more recent designs of Rogowski coils can be found in US patent 6313623.[1] In this patent there is a mention to an added purpose of the second wire returning through the center of the toroid, claiming that it helps reject interference from electrical fields present in the environment.

A device similar to the Rogowski coil was described by Arthur Prince Chattock of Bristol University in 1887.[2] Chattock used it to measure magnetic fields rather than currents. The definitive description was given by Walter Rogowski and W. Steinhaus in 1912.[3]

More recently, low-cost current sensors based on the principle of a Rogowski coil have been developed.[4] These sensors share the principles of a Rogowski coil, measuring the rate of change of current using a transformer with no magnetic core. The difference from the traditional Rogowski coil is that the sensor can be manufactured using a planar coil rather than a toroidal coil. In order to reject the influence of conductors outside the sensor's measurement region, these planar Rogowski current sensors use a concentric coil geometry instead of a toroidal geometry to limit the response to external fields. The main advantage of the planar Rogowski current sensor is that the coil winding precision that is a requirement for accuracy can be achieved using low-cost printed circuit board manufacturing.

Contents |

Formulae

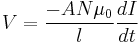

The voltage produced by a Rogowski coil is

,

,

where  is the area of one of the small loops, N is the number of turns, and

is the area of one of the small loops, N is the number of turns, and  is the length of the winding.

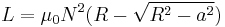

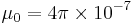

is the length of the winding.  is the rate of change of the current threading the loop. This formula assumes the turns are evenly spaced and that these turns are small relative to the radius of the coil itself. At high frequencies, the Rogowski coil's inductance will decrease its output. The inductance of a toroid is

is the rate of change of the current threading the loop. This formula assumes the turns are evenly spaced and that these turns are small relative to the radius of the coil itself. At high frequencies, the Rogowski coil's inductance will decrease its output. The inductance of a toroid is

is the magnetic constant,

is the magnetic constant,  is the major radius of the toroid, and

is the major radius of the toroid, and  is its minor radius.

is its minor radius.

See also

- Current

- Current transformer

- List of electronics topics

- Pulsed power

- Toroidal inductors and transformers

External links

- Miniature Wideband Current Probe sensor using this principle

- ABB Middle Voltage CSG/RMU uses Rogowski coil sensors

- PEM UK Rogowski current transducer theory

References

- ^ High precision rogowski coil, Ljubomir A. Kojovic et al. U.S. Patent 6,313,623, granted in Nov 6, 2001.

- ^ "On a magnetic potentiometer", Philosophical Magazine and Journal of Science, vol. XXIV, no. 5th Series, pp. 94–96, Jul-Dec 1887

- ^ Walter Rogowski and W. Steinhaus in "Die Messung der magnetischen Spannung", Archiv für Elektrotechnik, 1912, 1, Pt.4, pp. 141–150.

- ^ Patent for a planar Rogowski current sensor U.S. Patent 6,414,475, granted 2 Jul 2002.